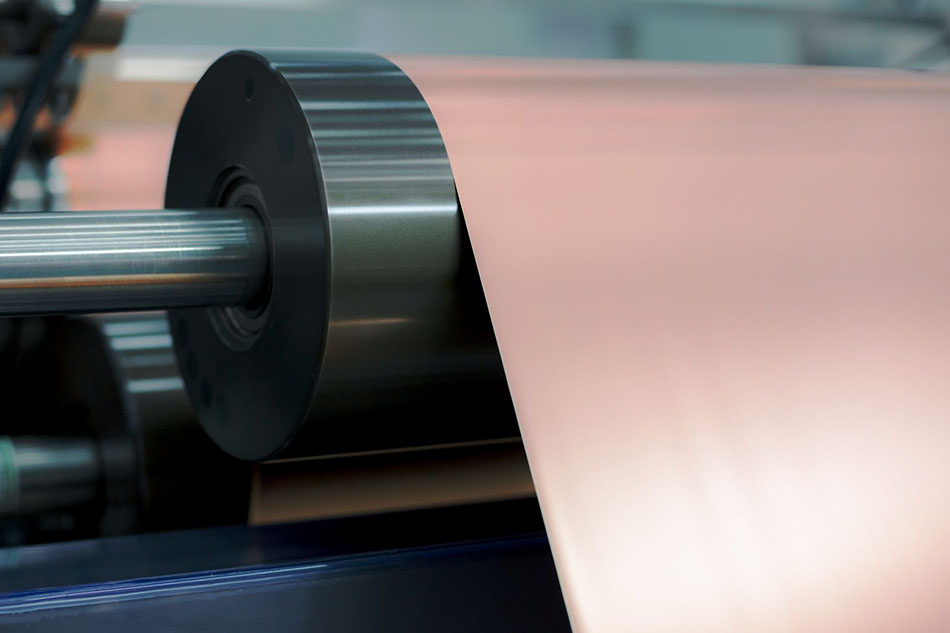

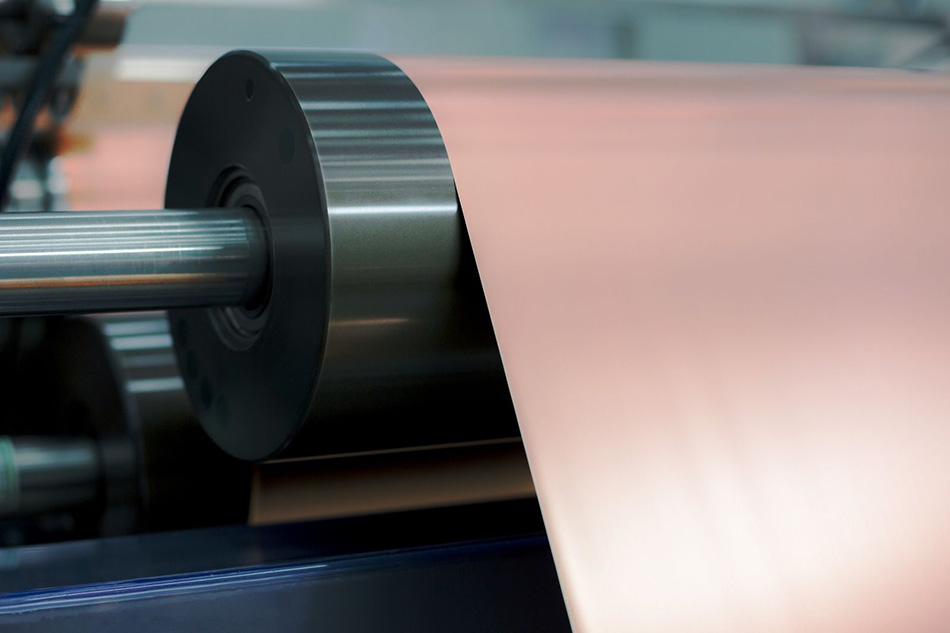

Best quality Copper Foil Thickness - Matte Side Treatment Very Low Profile Copper in Black/red (VLP-S-B/R) – JM

Best quality Copper Foil Thickness - Matte Side Treatment Very Low Profile Copper in Black/red (VLP-S-B/R) – JM Detail:

The raw foil, which has a glossy surface with ultra low roughness on both sides, is treated with JIMA’s proprietary micro-roughening process to achieve high anchoring performance and also ultra low roughness. It offers high performance in a wide range of fields, from rigid printed circuit boards that prioritize transmission properties and fabrication of fine pattern to flexible printed circuits that prioritize transparency.

Detail

● ID: 76 mm, 152 mm

● Roll Length/Outer diameter/Inner diameter: as request

● Core length: as request

● Core material: Paper and ABS plastic & Customize

● Sample can be supply

● Inner Package: can supply Vacuum packaging if need

Features

● Low profile for FCCL

● Grain structure of copper foil leads to high flexibility

● Excellent etching performance

● The treated foil is red or black

● Low profile enables to make fine circuit pattern

Typical application

● Casting and lamination type FCCL

● Fine pattern FPC&PWB

● Chip on flex for LED

● For FPC or Inner layer

● For a wide range of applications, from circuit boards to optics.

Typical properties of Matte Side Treatment Low Profile Copper Foil

| Classification |

Unit |

Requirement |

Test Method |

|||||

|

Nominal thickness |

Um |

10 |

12 |

16 |

25 |

35 |

IPC-4562A |

|

|

Area Weight |

g/m² |

98±4 |

107±4 |

153± 5 |

228± 8 |

285±10 |

IPC-TM-650 2.2.12.2 |

|

|

Purity |

% |

≥99.8 |

IPC-TM-650 2.3.15 |

|||||

|

roughness |

Shiny side (Ra) |

սm |

≤2.5 |

≤2.5 |

≤2.5 |

≤2.5 |

≤2.5 |

IPC-TM-650 2.3.17 |

|

Matte side(Rz) |

um |

≤4.0 |

≤4.5 |

≤5.5 |

≤6.0 |

≤8.0 |

||

|

Tensile Strength |

R.T.(23°C) |

Mpa |

≥260 |

≥260 |

≥280 |

≥280 |

≥280 |

IPC-TM-650 2.4.18 |

|

H.T.(180°C) |

≥180 |

≥180 |

≥180 |

≥180 |

≥180 |

|||

|

Elongation |

R.T.(23°C) |

% |

≥5 |

≥6 |

≥8 |

≥10 |

≥12 |

IPC-TM-650 2.4.18 |

|

|

H.T.(180°C) |

≥5 |

≥6 |

≥7 |

≥8 |

≥8 |

||

|

Peel Strength(FR-4) |

N/mm |

≥0.7 |

0.8 |

1.0 |

1.1 |

1.2 |

IPC-TM-650 2.4.8 |

|

|

|

lbs/in |

≥4 |

≥4.6 |

≥5.7 |

≥6.3 |

≥6.9 |

||

|

Pinholes & porosity |

Number |

No |

IPC-TM-650 2.1.2 |

|||||

|

Anti-oxidization |

R.T.(23°C) |

|

180 |

|

||||

|

R.T.(200°C) |

|

60 |

||||||

Standard Width: 520mm 1040mm 1100mm, Max.1300mm May according to the customer request tailor.

Product detail pictures:

Related Product Guide:

Our objective is to present premium quality products at aggressive prices, and top-notch services to buyers around the world. We have been ISO9001, CE, and GS certified and strictly adhere to their excellent specifications for Best quality Copper Foil Thickness - Matte Side Treatment Very Low Profile Copper in Black/red (VLP-S-B/R) – JM , The product will supply to all over the world, such as: Borussia Dortmund, Congo, Peru, Merchandise have been exported to Asia, Mid-east,European and Germany market. Our company has constantly been able to update the items performance and safety to meet the markets and strive to be top A on stable quality and sincere service. If you have the honor to do business with our company. we'll undoubtedly do our very best to support your business in China.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.