Good Quality Treated Rolled Copper Foil - Rolled Copper Foil For Graphene – JM

Good Quality Treated Rolled Copper Foil - Rolled Copper Foil For Graphene – JM Detail:

High Precision Rolled Copper Foil

|

Item |

Alloy |

Thickness (um) |

width(mm) |

Application |

|

Rolled copper foil for graphene |

C1020 |

12um 18um 25um 35um 50um |

≤630 |

Grapheme conductive film production |

|

Rolled Copper Foil with Black/red treatment |

C1100 |

6um 9um 12um 18um 22um 35um 50um 70um |

≤630 |

Flexibility LED, FCCL, Flexible Printed Circuit, flexible copper clad plate, |

|

Plain Copper Foil |

C1100 |

6um 9um 12um 18um 35um 50um 70um |

≤630 |

Energy storage, Power., Electric Vehicles Li-ion Battery, 5G Mobile antenna/ 5G communication, Heat dissipation |

|

High corrosion resistance rolled copper foil(RA Copper Foil _with Nickel plating) |

C1100 |

12um 18um 25um 35um 50um |

≤630 |

Mess mobile model. will be applied almost of Samsung mobile device |

Specification

● Details Packaging: Wooden box package

● The product is up to the ROHS environmental standards

● ID: 76 mm

● Length: Customized

● Sample can supply support

● Roll Length an core length: as per request

● Roll inner diameter and outer diameter: as request

Application Field

● Graphene thermal conductive film/Grapheme conductive film production

● Flexible graphene smartphone

● Widely used in many fields such as chemistry, biology, electronic information

● Graphene copper foil used for Physics, materials, electronic information, computers

● Chemical sensor, Transistor, consumer electronics(Flexible display screen).

● Catalyst

● Supercapacitors

● Solar energy

● Graphene semiconductor chips

● Conductive graphene film

● Graphene computer memory

● Biomaterials

● Transparent conductive coatings

● Aerospace and military industry

Typical Properties Of Rolled Copper Foil For Graphene

|

Classification |

Unit |

Requirement |

Test Method |

||||

|

Nominal thickness |

Um |

12 |

18 |

35 |

70 |

105 |

GB/T29847-2013 |

|

Area Weight |

g/m² |

107±5 |

153±7 |

285± 10 |

585± 20 |

870±30 |

GB/T29847-2013 |

|

Cu Purity(C1020) |

% |

≥99.99 |

GB/T5121 |

||||

|

Surface roughness |

սm |

≤0.08 |

≤0.08 |

≤0.08 |

≤0.08 |

≤0.08 |

GB/T29847-2013 |

|

Tensile Strength |

N/m² |

440-470 |

450-480 |

450-470 |

440-460 |

410-450 |

GB/129847-2013 |

|

Elongation Rate |

% |

1.0-1.2 |

1.0-1.2 |

1.1-1.3 |

1.1-1.4 |

1.1-1.5 |

GB/129847-2013 |

|

Surface Quality |

No Wrinkle, No Color Difference, No Scratche, No Pit and Salient Point |

||||||

|

Storage Condition |

Temperature≤25°C, Relative Humidity≤60%, 180 days |

||||||

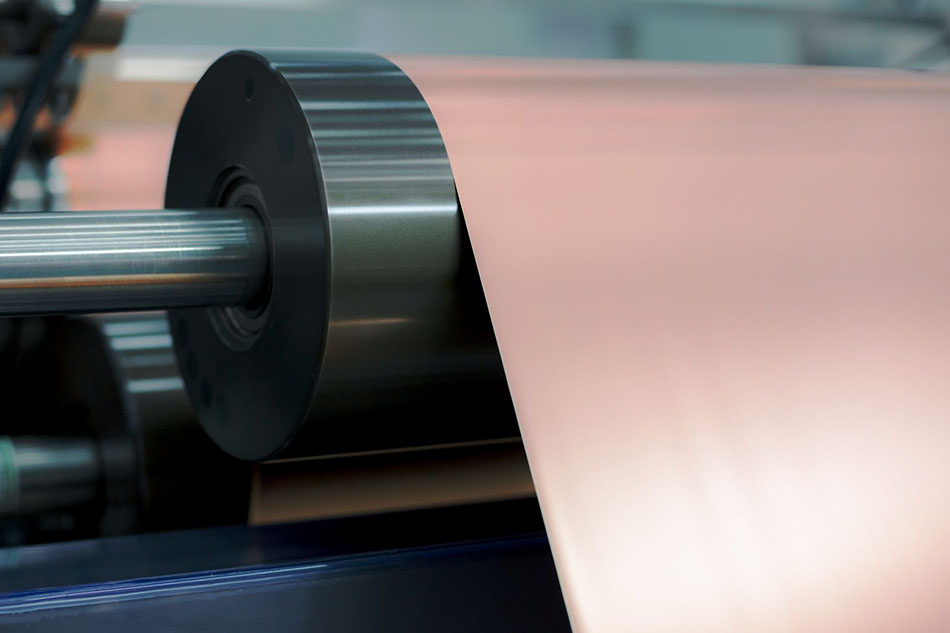

Products Photos & Wooden Box Package Photos

Product detail pictures:

Related Product Guide:

Our business aims to operating faithfully, serving to all of our clients , and working in new technology and new machine continuously for Good Quality Treated Rolled Copper Foil - Rolled Copper Foil For Graphene – JM , The product will supply to all over the world, such as: United Kingdom, Malta, Thailand, Our advantages are our innovation, flexibility and reliability which have been built during last 20 years. We focus on providing service for our clients as a key element in strengthening our long-term relationships. The continual availability of high grade products in combination with our excellent pre- and after-sales service ensures strong competitiveness in an increasingly globalized market.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.