High Quality Copper Coil - Low Coarsening Reverse Treated Copper Foil – JM

High Quality Copper Coil - Low Coarsening Reverse Treated Copper Foil – JM Detail:

Detail

● Thickness: 12um 18um 35um 70um

● Standard Width: 1290mm, we can do cutting as size requirement

● Wooden box package

● ID: 76 mm, 152 mm

● Length: Customized

● Sample can be supply

● Lead time: 15-30days

● Term: FOB, CIF…

● Payment item: 50%T/T deposit, balance pay before shipping.

Features

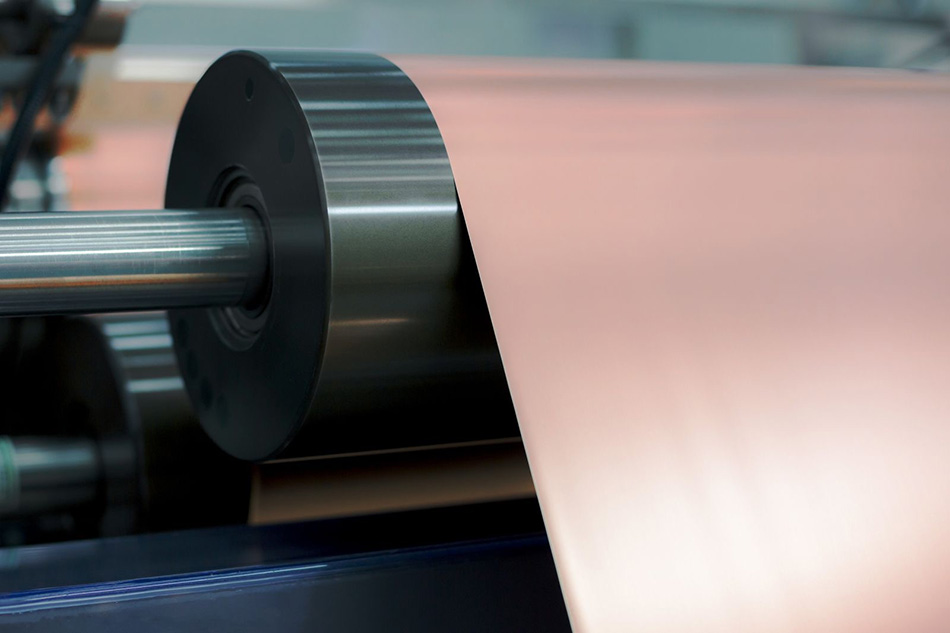

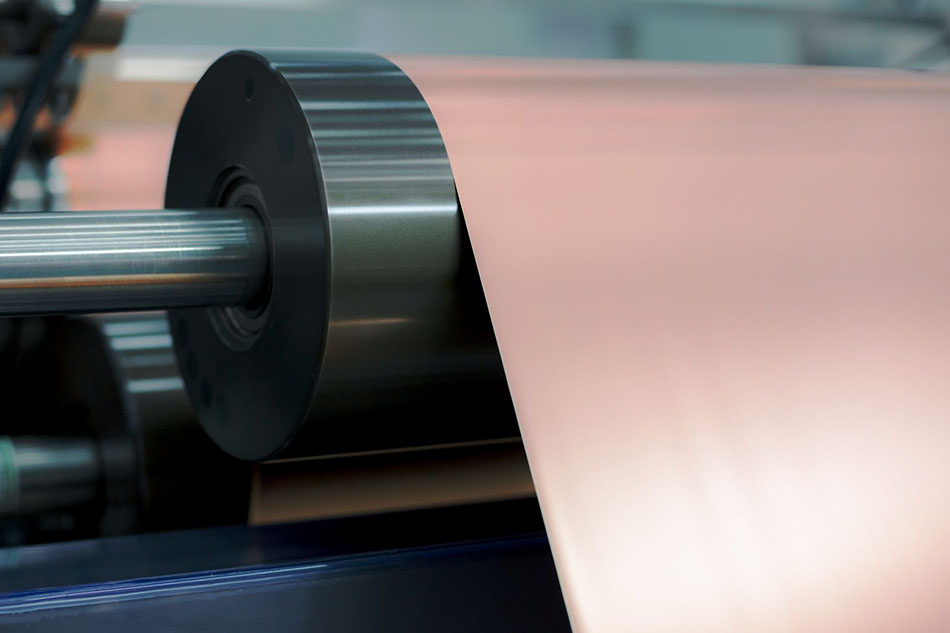

● Reverse treated copper foil

● Low profile, with high peel strength

● The treated foil is pink

● As reverse-treated copper foil, this product has better etchability performance. It can effectively shorten the production process, achieve higher speed and fast micro-etching, and improve the conformance rate of PCBs.

Application

● High frequency, Ultra -high frequency, applying to PPE board

● Fine circuit pattern

● It is mainly applied in multilayered boards and high-frequency boards.

Typical Properties of Low Coarsening Reverse Treated Copper Foil

|

Classification |

Unit |

Requirement |

Test Method |

|||||

|

Nominal thickness |

um |

12 |

18 |

35 |

70 |

IPC-4562A |

||

|

Area Weight |

g/m² |

107±5 |

153±7 |

285± 10 |

585± 20 |

IPC-TM-650 2.2.12 |

||

|

Purity |

% |

≥99.8 |

IPC-TM-650 2.3.15 |

|||||

|

Roughness |

Shiny side (Ra) |

um |

3.0 |

IPC-TM-650 2.2.17 |

||||

|

Matte side(Rz) |

um |

≤5.0 |

≤6.0 |

≤8.0 |

≤10 |

|||

|

Tensile Strength |

R.T.(23°C) |

Mpa |

≥276 |

IPC-TM-650 2.4.18 |

||||

|

H.T.(180°C) |

≥138 |

|||||||

|

Elongation |

R.T.(23°C) |

% |

≥4 |

≥4 |

≥8 |

≥12 |

IPC-TM-650 2.4.18 |

|

|

H.T.(180°C) |

≥3 |

≥4 |

≥4 |

≥4 |

||||

|

Peel Strength(FR-4) |

N/mm |

≥1.0 |

≥1.2 |

≥1.4 |

≥1.8 |

IPC-TM-650 2.4.8 |

||

|

Lbs/in |

≥5.7 |

≥7.4 |

≥8.0 |

≥10.2 |

||||

|

Pinholes & porosity |

Numbers |

No |

IPC-TM-650 2.1.2 |

|||||

|

Anti-oxidization |

R.T.(23°C) |

Days |

90 |

|

||||

|

H.T.(200°C) |

Minutes |

30 |

||||||

Standard Width,1295(±1)mm, Width range:200-1340mm. May according to the customer request tailor.

Electrolytic copper foil Image

Product detail pictures:

Related Product Guide:

With our leading technology also as our spirit of innovation,mutual cooperation, benefits and development, we are going to build a prosperous future jointly with your esteemed company for High Quality Copper Coil - Low Coarsening Reverse Treated Copper Foil – JM , The product will supply to all over the world, such as: Frankfurt, Melbourne, Ghana, The quality of our merchandise is equal to OEM's quality, because our core parts are the same with OEM supplier. The above items have passed professional certification, and we not only can produce OEM-standard items but we also accept Customized Merchandise order.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.