Manufacturer for Reverse Treated Electrodeposited Copper Foil - Electric Vehicles Li-ion Battery Double Side Shiny Copper Foil – JM

Manufacturer for Reverse Treated Electrodeposited Copper Foil - Electric Vehicles Li-ion Battery Double Side Shiny Copper Foil – JM Detail:

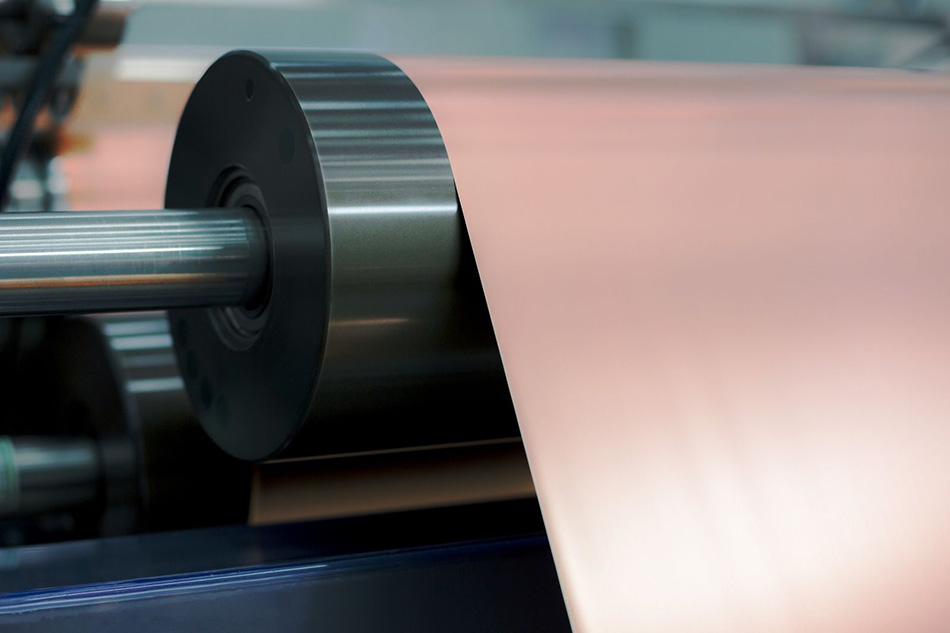

Double-sided polished electrolytic copper foil is characterized by a symmetrical structure of two sides, metal density close to the theoretical density of copper, very low profile of the surface, excellent elongation and tensile strength, and so forth. As the cathode collector for lithium batteries, it has excellent cold/thermal resistance and can significantly extend the battery longevity. It can be widely applied in batteries for new-energy vehicles, the 3C industry represented by smart phones, notebook computers, and the ESS storage system, and space.

Detail

● Thickness: 4.5um 5um 6um 8um 9um 10um 12um

● Width: can be cutting as size request.

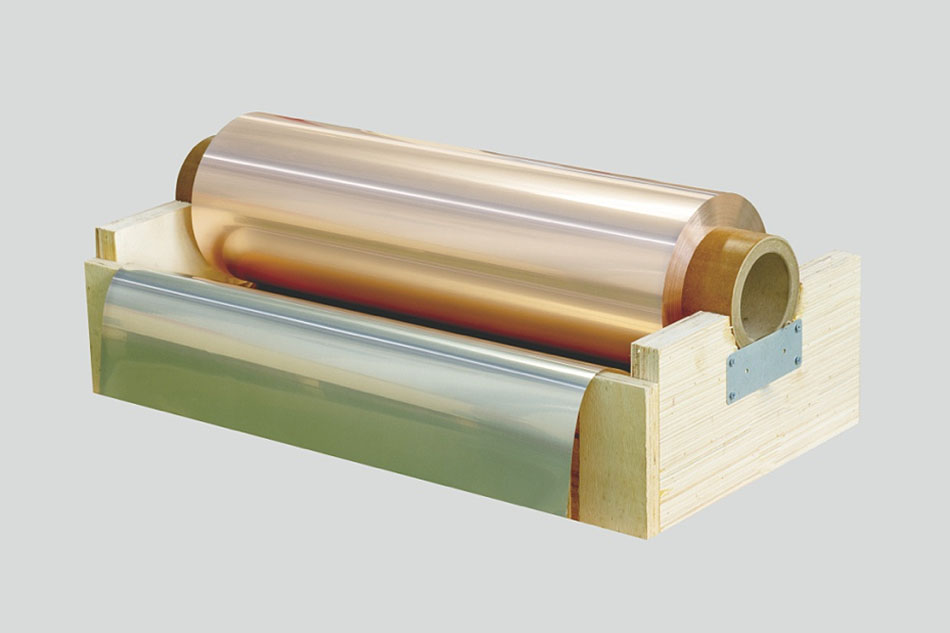

● Wooden box package, Inner Package: can supply Vacuum packaging if need

● ID: 76 mm, 152 mm

● Length: Customized

● Sample can be supply

● Roll Length/Outer diameter/Inner diameter: as request

● Core length: as request

● Core material: Paper and ABS plastic & Customize

Features

● Glossy both side superior rupture endurance

● Stable properties suitable for high capacity rechargeable battery

● Eco-friendly products and processes

● Excellent uniformity

● Excellent infiltration

Typical application

● Electric Vehicles

● Li-ion Battery (LiB)

● Notebook PC

● Mobile phone

● Capacitor

Typical Properties of Li-ion Battery Double-side Shiny ED Copper Foil

|

Classification |

Unit |

Requirement |

Test Method |

|||||

|

Nominal thickness |

Um |

6 |

8 |

9 |

10 |

12 |

IPC-4562A |

|

|

Area Weight |

g/m² |

54±2 |

70-75 |

85-90 |

95-100 |

105-110 |

IPC-TM-650 2.2.12.2 |

|

|

Purity |

% |

≥99.9 |

IPC-TM-650 2.3.15 |

|||||

|

roughness |

Shiny side (Ra) |

սm |

≤0.43 |

≤0.43 |

≤0.43 |

≤0.43 |

≤0.43 |

IPC-TM-650 2.3.17 |

|

Matte side(Rz) |

um |

≤3.0 |

≤3.0 |

≤3.0 |

≤3.0 |

≤3。0 |

||

|

Tensile Strength |

R.T.(23°C) |

Mpa |

≥294 |

≥294 |

≥294 |

≥294 |

≥294 |

IPC-TM-650 2.4.18 |

|

H.T.(180°C) |

≥196 |

≥196 |

≥196 |

≥196 |

≥196 |

|||

|

Elongation |

R.T.(23°C) |

% |

≥5 |

≥5 |

≥5 |

≥5 |

≥5 |

IPC-TM-650 2.4.18 |

|

H.T.(180°C) |

≥3 |

≥3 |

≥3 |

≥3 |

≥3 |

|||

|

Pinholes & porosity |

Number |

No |

IPC-TM-650 2.1.2 |

|||||

|

Anti-oxidization |

R.T.(23°C) |

|

90 |

|

||||

|

R.T.(160°C) |

|

15 |

|

|||||

Product detail pictures:

Related Product Guide:

It can be our accountability to satisfy your preferences and competently provide you. Your satisfaction is our greatest reward. We are searching ahead towards your visit for joint growth for Manufacturer for Reverse Treated Electrodeposited Copper Foil - Electric Vehicles Li-ion Battery Double Side Shiny Copper Foil – JM , The product will supply to all over the world, such as: Nepal, America, Florida, We are proud to supply our products to every costumer all around the world with our flexible, fast efficient services and strictest quality control standard which has always approved and praised by customers.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.