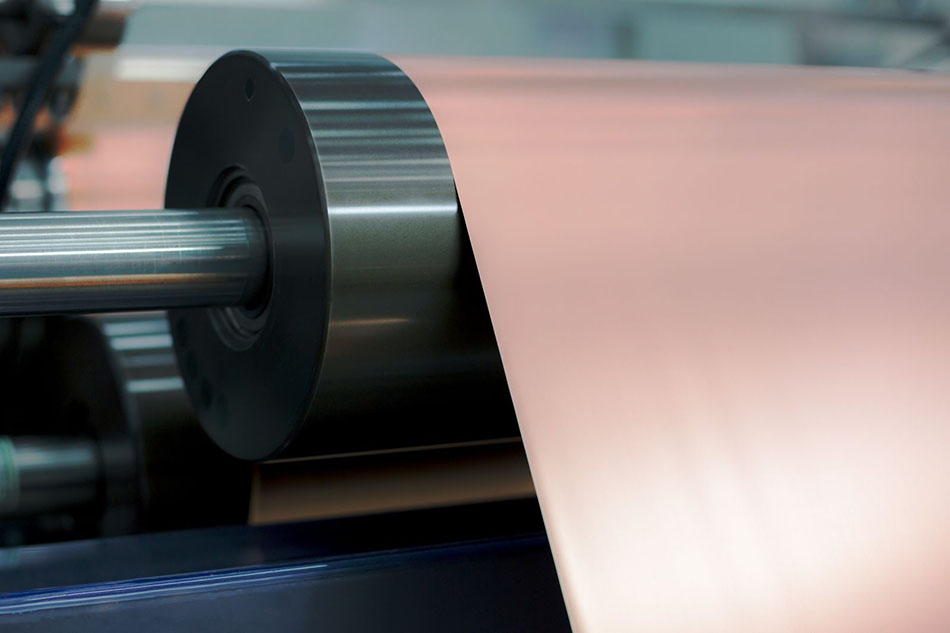

One of Hottest for Copper Foil Insulation - Reverse Treated Electrolytic Copper Foil – JM

One of Hottest for Copper Foil Insulation - Reverse Treated Electrolytic Copper Foil – JM Detail:

Detail

● Thickness: 12um 18um 35um 70um

● Standard Width: 1290mm, range: 300-1300mm, can be cutting as size request.

● Wooden box package

● ID: 76 mm, 152 mm

● Length: Customized

● Sample can be supply

● High precision cutting equipment cut copper foils according to width required by customers.

● The electron microscope and energy disperse spectroscopy equipment guarantee the quality of final product before delivery.

Features

● Reverse treated copper foil

● Low profile, with high peel strength

● Excellent etchability

● The treated foil is pink

Application

● High frequency, applying to hydrocarbon board

● High Tg

● Fine circuit pattern

Typical properties of Reverse Treated Electrolytic Copper Foil

|

Classification |

Unit |

Requirement |

|

|

|

Test Method |

||

|

Nominal thickness |

um |

12 |

18 |

35 |

70 |

IPC-4562A |

||

|

Area Weight |

g/m² |

107±5 |

153±7 |

285± 10 |

585± 20 |

IPC-TM-650 2.2.12 |

||

|

Purity |

% |

≥99.8 |

IPC-TM-650 2.3.15 |

|||||

|

Roughness |

Shiny side (Ra) |

um |

4.0 |

IPC-TM-650 2.2.17 |

||||

|

Matte side(Rz) |

um |

≤5.0 |

≤6.0 |

≤8.0 |

≤10 |

|||

|

Tensile Strength |

R.T.(23°C) |

Mpa |

≥276 |

IPC-TM-650 2.4.18 |

||||

|

H.T.(180°C) |

≥138 |

|||||||

|

Elongation |

R.T.(23°C) |

% |

≥4 |

≥4 |

≥8 |

≥12 |

IPC-TM-650 2.4.18 |

|

|

H.T.(180°C) |

≥3 |

≥4 |

≥4 |

≥4 |

||||

|

Peel Strength(FR-4) |

N/mm |

≥1.0 |

≥1.2 |

≥1.4 |

≥1.8 |

IPC-TM-650 2.4.8 |

||

|

Lbs/in |

≥5.7 |

≥7.4 |

≥8.0 |

≥10.2 |

||||

|

Pinholes & porosity |

Numbers |

No |

IPC-TM-650 2.1.2 |

|||||

|

Anti-oxidization |

R.T.(23°C) |

Days |

90 |

|

||||

|

H.T.(200°C) |

Minutes |

40 |

||||||

Standard Width, 1295(±1)mm, Width range: 200-1340mm. May according to the customer request tailor.

Product detail pictures:

Related Product Guide:

Our firm since its inception, normally regards item top quality as company life, constantly make improvements to generation technology, improve product excellent and repeatedly strengthen organization total good quality management, in strict accordance with the national standard ISO 9001:2000 for One of Hottest for Copper Foil Insulation - Reverse Treated Electrolytic Copper Foil – JM , The product will supply to all over the world, such as: Netherlands, Mexico, Hungary, The design, processing, purchasing, inspection, storage, assembling process are all in scientific and effective documentary process , increasing usage level and reliability of our brand deeply, which makes us become superior supplier of the four major product categories shell castings domestically and obtained the customer's trust well.

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!