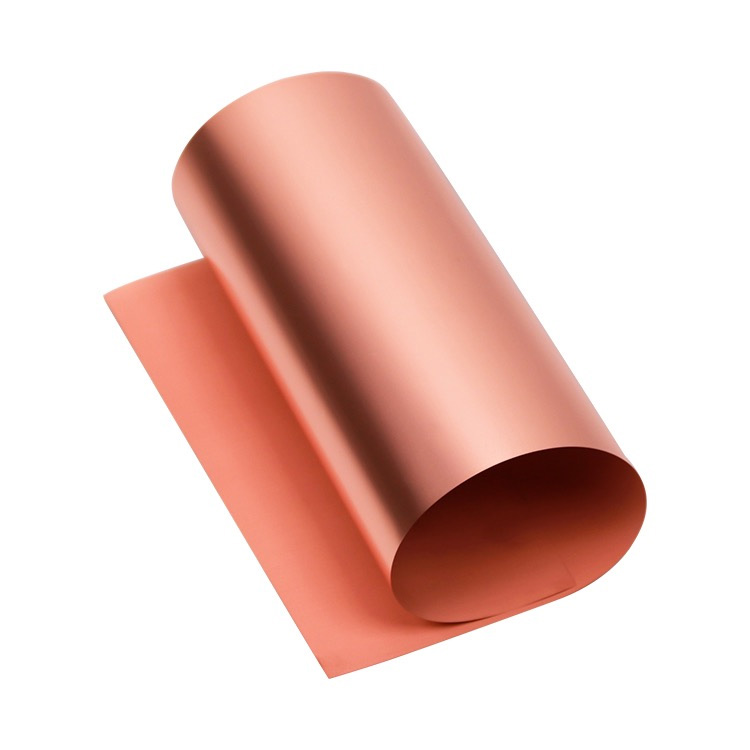

Double Side Treated Copper foil For HDI

● Thickness: 12um 18um 35um 70um

● Standard Width: 1290mm, We can cutting as size requirement

● ID: 76 mm, 152 mm

● Length: Customized

● Sample can be supply; Lead time: 7days

● Delivery time: 15-20days

● Packing details: Export Wooden box

● Term: FOB, CIF.

● Payment item: 50%T/T deposit, balance pay before shipping.

● High performance processing disposal equipment perform fabrication processing of copper foil.

● Double-side treated Copper foil

● With high binding force to laminate

● Direct multi-layer lamination

● Good etchability

● The treated foil is pink

● Multilayer Printed Circuit Board

● HDI (High Density Interconnector) for PCB

|

Classification |

Unit |

Requirement |

Test Method |

||||||

|

Foil Designation |

|

T |

H |

1 |

2 |

IPC-4562A |

|||

|

Nominal thickness |

um |

12 |

18 |

35 |

70 |

IPC-4562A |

|||

|

Area Weight |

g/m² |

107±5 |

153±7 |

285± 10 |

585± 20 |

IPC-TM-650 2.2.12 |

|||

|

Purity |

% |

≥99.8 |

IPC-TM-650 2.3.15 |

||||||

|

Roughness |

Shiny side (Ra) |

um |

≤3.0 |

IPC-TM-650 2.2.17 |

|||||

|

Matte side(Rz) |

um |

≤6 |

≤8 |

≤10 |

≤15 |

||||

|

Tensile Strength |

R.T.(23°C) |

Mpa |

≥207 |

≥207 |

≥276 |

≥276 |

IPC-TM-650 2.4.18 |

||

|

H.T.(180°C) |

≥103 |

≥103 |

≥138 |

≥138 |

|||||

|

Elongation |

R.T.(23°C) |

% |

≥2 |

≥2 |

≥3 |

≥3 |

IPC-TM-650 2.4.18 |

||

|

H.T.(180°C) |

≥2 |

≥2 |

≥2 |

≥3 |

|||||

|

Resistivity |

Ωg/m² |

≤0.170 |

≤0.166 |

≤0.162 |

≤0.162 |

IPC-TM-650 2.5.14 |

|||

|

Peel Strength(FR-4) |

S side |

N/mm |

≥0.9 |

≥0.9 |

≥1.4 |

≥1.4 |

IPC-TM-650 2.4.8 |

||

|

Lbs/in |

≥5.1 |

≥6.3 |

≥8.0 |

≥8.0 |

|||||

|

M side |

N/mm |

≥0.9 |

≥1.1 |

≥1.4 |

≥2.0 |

||||

|

Lbs/in |

≥5.1 |

≥6.3 |

≥8.0 |

≥11.4 |

|||||

|

Pinholes & porosity |

Numbers |

No |

IPC-TM-650 2.1.2 |

||||||

|

Anti-oxidization |

R.T.(23°C) |

Days |

180 |

/ |

|||||

|

H.T.(200°C) |

Minutes |

40 |

/ |

||||||

Standard Width,1295(±1)mm, Width range:200-1340mm. May according to the customer request tailor.

PCB Copper Foil Image