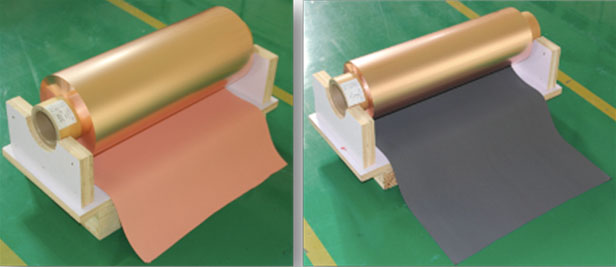

Matte Side Treated Low Profiles Rolled Copper Foil Black and red color

Treated Low Profiles Rolled Copper Foil with Black/Red Matte Side

Rolled Copper Foil characteristic

During the downstream heating process, the material will undergo annealing changes at a temperature of 145°C within half an hour, The tensile strength and hardness of the material are reduced, and so the elongation is greatly increased, which provides sufficient elongation for the later bending and stretching of the flexible LED, The finished LED is not easy to break during the stretching and bending process.

● The treated rolled copper foil with red matte side

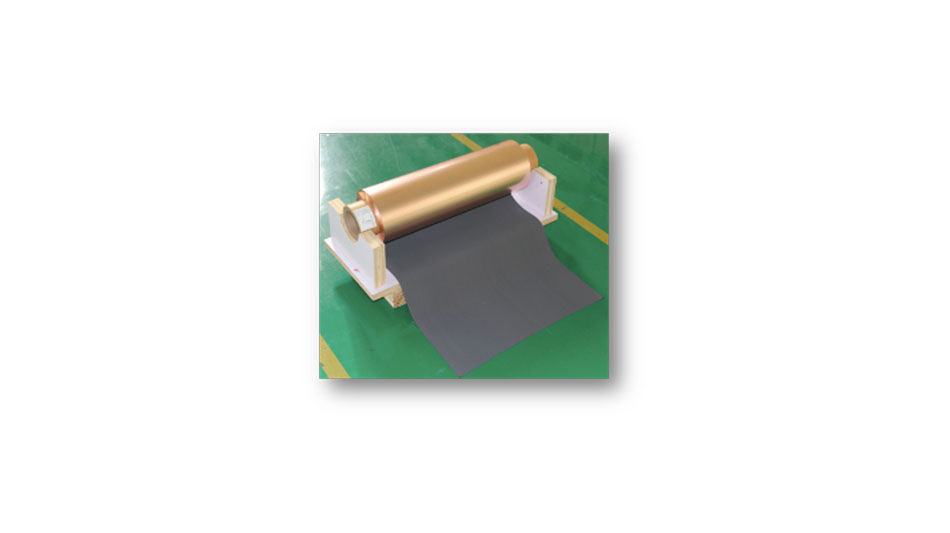

● The treated rolled copper foil with black matte side

● Thickness: 9um 12um 18um 22um 35um 50um 70um

● Width: 250~630mm, standard width: 520mm, can be cutting as request

● Wooden box package

● The product is up to the ROHS environmental standards

● ID: 76 mm

● Length: Customized

● Sample can supply support

● Roll Length an core length: as per request

● Roll inner diameter and outer diameter: as request

● Low roughness

● High Flexibility

● Excellent Etching Performance

● The treated foil in black or red

● The blackened foil has high flexibility, low surface roughness and good physical and chemical properties.

● Apply to FPC (Flexible Printed Circuit) use fields: Informatization and intelligentization; Higher-end product field such as Aerospace, Medical apparatus and instruments, Robots, Communication System, Computers and automotive electronics.

● Apply to FCCL/ Flexible copper clad plate

● Apply to flexibility LED, high-end flexible LED and flexible mobile phone circuit boards and other high-end fields

● Flexible Printed Circuit

|

Classification |

Unit |

Test Method |

||||||||||||||

|

Nominal thickness |

Um |

9 |

12 |

18um |

35um |

22um |

50um |

70um |

Test Method |

|||||||

|

Area Weight |

g/m² |

80±2 |

107±3 |

160±4 |

311±5 |

196±4 |

445±5 |

623±5 |

GB/T29847-2013 |

|||||||

|

Purity |

% |

Min.99.97 |

GB/T5121 |

|||||||||||||

|

Surface roughness |

Shiny side (Ra) |

Um |

Max.0.2 |

GB/T29847-2013 |

||||||||||||

|

Matte side (Rz) |

Um |

0.8-1.2 |

||||||||||||||

|

Tensile Strength |

Rm Normal |

N/mm² |

≥370 |

≥370 |

≥370 |

≥370 |

≥370 |

≥370 |

≥370 |

GB/T29847-2013 |

||||||

|

|

|

|

|

|

||||||||||||

|

Rm 180°C*30min. |

≥160 |

≥160 |

≥160 |

≥170 |

≥170 |

≥170 |

≥170 |

|||||||||

|

Elongation |

Normal |

% |

≥1.0 |

≥1.0 |

≥1.0 |

≥1.0 |

≥1.0 |

≥1.0 |

1≥1.0 |

GB/T29847-2013 |

||||||

|

180°C*30min |

≥7 |

≥7 |

≥8 |

≥11 |

≥9 |

≥13 |

≥20 |

|||||||||

|

Peel Strength |

N/mm |

≥0.8 |

≥0.8 |

≥1.0 |

≥1.2 |

≥1.0 |

≥1.4 |

≥2.0 |

GB/T29847-2013 |

|||||||

|

Surface Quality |

/ |

Uniform Color, No Wrinkle, No Scratche, No Pit and Salient Point |

||||||||||||||

|

Chemical Resistance |

% |

Max.5 |

||||||||||||||

|

Oxidation Resistance |

200°C/60min |

Non-discoloring |

Q/TBJB004-2015 |

|||||||||||||

|

Solder Resistance |

|

300°C/20s No blisters |

||||||||||||||

The product is up to the ROHS environmental standard.

Treated Low Profiles Rolled Copper Foil With Balck/Red Iamge